![]() Typical

automotive ignition module theory

Typical

automotive ignition module theory

![]() Yamaha partial

schematic diagram

Yamaha partial

schematic diagram

![]() Starter

interupt and flashing led.

Starter

interupt and flashing led.

- Starter and fuel (scr))

- Fuel kill (scr)

![]() Turn off your car stereo when you leave

Turn off your car stereo when you leave

![]() Light dimmer

control (uses battery)

Light dimmer

control (uses battery)

![]() 20 Minute timer full

diagram

20 Minute timer full

diagram

- 20 min timer 555 crude

![]() Water

valve pulser LM555 Monostable (updated)

Water

valve pulser LM555 Monostable (updated)

- Water valve pulser LM555 Monostable (crude version)

![]() Ignition adaptor

C140

Ignition adaptor

C140

BMW 318

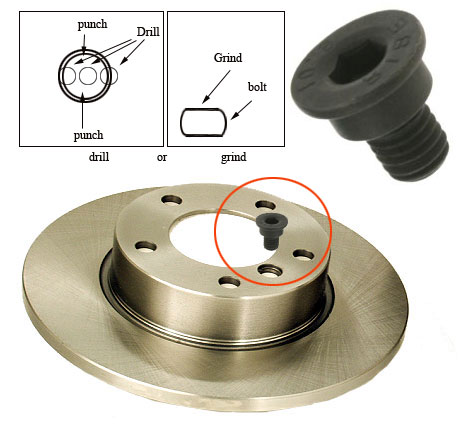

Today we replace all four rotors on the BMW. Two front rotors for $50 shipped and two back rotors made from Germany $90 shipped were installed easily.

The only major problem was that the Allen Head Bolt for Brake Disc to Hub bolt was rusted in place. It was drilled out. Yes, I'd used anti rust and flame then punch it out but it will not budge. Upon the haste I'd drilled the center of the bolt which is a no-no. The preferred way to to use an angle grinder as shown in method two below.

How to Drill the Allen Head Bolt for Brake Disc to Hub. Directions:

Drill out the head of the bolt when it's rusted and won't come loose.

Remove the hub and grind the bolt flush to the hub. Punch three spots

on the hub indicated by the arrows. Drill with a small drill bit then

increase in size. Punch out the bolt when the bolt is weak. Directions

for method 2: This is the preferred method. Grind the head

of the bolt with an angle grinder until the rotor can be

removed. Remove the rotor. Grind the bolt to form a rectangle

shape for a monkey wrench. Soak the bolt thread with a bolt

remover formula. Use the monkey wrench to loosen the bolt.

Check out how I grind the nut to fit a monkey wrench.

The rear rotor was installed without problems. Upon installation I coat the rotor (not the rotor pad surface) with varnish to prevent rust. I used grease on the Allen Head Bolt and installed it. I use anti seize compounds on the wheel to hub nut and torque to 80lb-ft.

The other problem with the BMW is that the suspension is loose when driving on a bumpy surface at high speeds. The front suspensions are check and there were no wear found .

Other problems faced with the car:

- Window track broke. Was fixed with stainless steel wire. As good

as new since a year ago.

- Electric gas lid popper electric wire was open. The wire was

rerouted.

- The hand brake light on dash keeps coming on. The fix is to take the instrument gauge out and bang on the instrument a bit and install it back in. Apparently, a loose wire is inside the instrument gauge is the culprit. I'd never got the gauge out because I didn't want to remove the steering wheel and airbag.

- Radiator exploded.

- Radiator fan resistor rusted and open.

- Windshield broke. Caused from leaning on plastic laundry basket

at the driver seat position which smashed against the front windshield which formed a

hairline crack. (A $400 windshield repair.)

- One modification made: An inner trunk popper was made in case

the driver is locked in the trunk. A steel cable is strung to the

release lever and protrude outside of the panel with a handle for

who ever is locked in the trunk to pull if needed.

Voltage-Current-Resistance-Power CALCULATOR click here

BMW 318i image only

TDI Golf joke